Healthcare supply chain management has reached a critical juncture where traditional approaches no longer suffice to meet the complex demands of modern healthcare delivery. With nearly 80% of healthcare providers and 84% of suppliers expecting supply chain challenges to worsen or remain unchanged over the next year, organizations must confront systemic issues that directly impact patient care, operational efficiency, and financial performance.

The ripple effects of supply chain disruptions extend far beyond procurement departments, affecting clinical outcomes, patient satisfaction, and organizational resilience. Healthcare leaders must understand these challenges and implement strategic solutions to ensure sustainable operations while maintaining the highest standards of patient care.

Critical Supply Chain Challenges Impacting Healthcare Operations

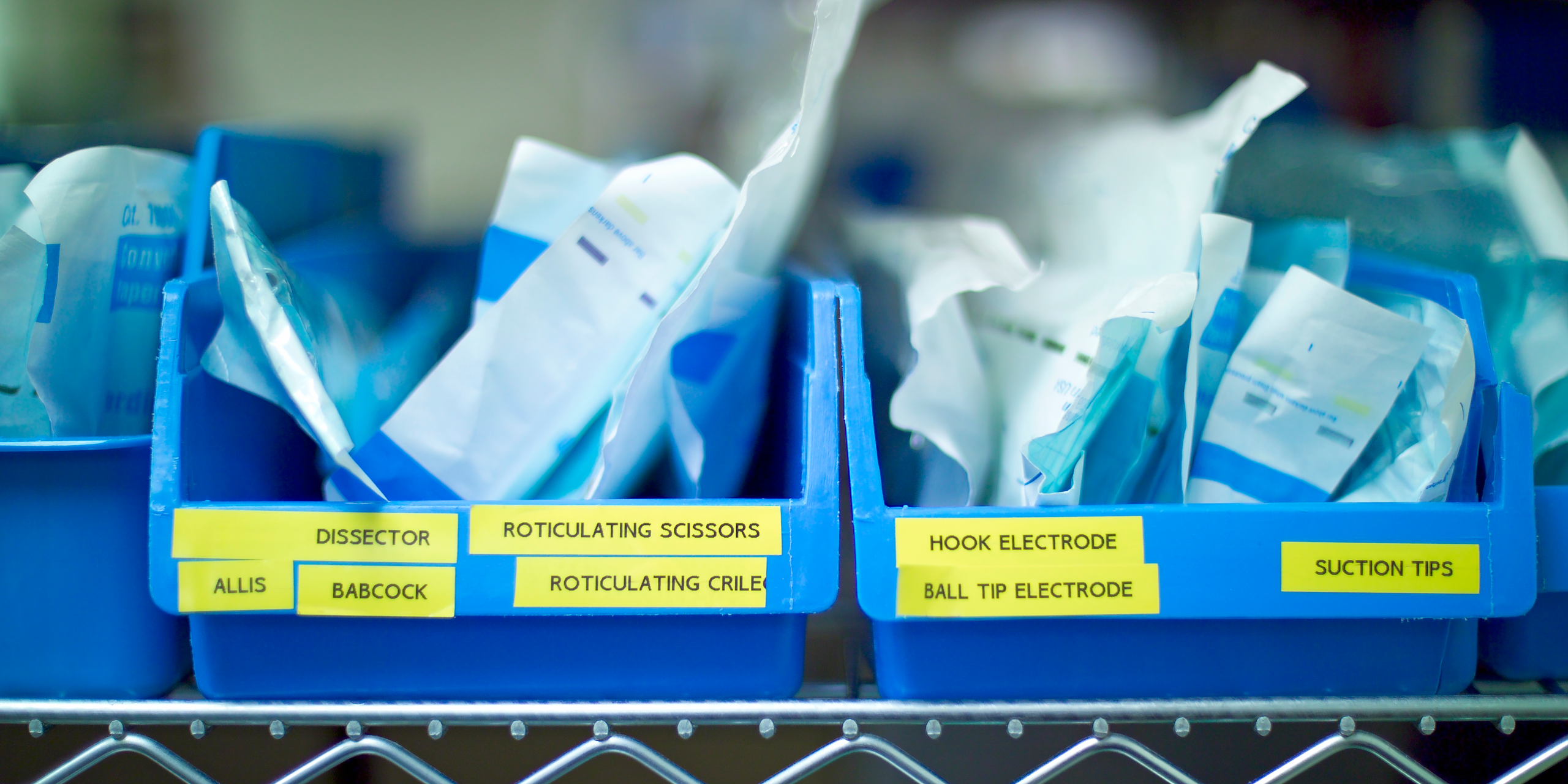

Drug and Medical Supply Shortages

Medication shortages represent one of the most persistent and dangerous challenges facing healthcare organizations today. Manufacturing quality issues serve as the primary cause of drug shortages, compounded by production delays, raw material procurement challenges, and barriers to onboarding alternative suppliers during disruptions.

These shortages create cascading effects throughout healthcare systems. Clinical teams must identify therapeutic alternatives, often requiring additional training and protocol adjustments. Pharmacy departments face increased workload managing substitute medications, while procurement teams scramble to secure supplies from alternative sources at premium costs.

The financial impact extends beyond direct procurement costs. Across multiple studies, providers and clinical staff report spending significant time mitigating supply chain challenges and shortages, representing significant opportunity costs that could otherwise support patient care activities.

Personal Protective Equipment Availability

Personal protective equipment availability continues to challenge healthcare organizations, particularly during surge periods or global disruptions. Supply chain disruptions affect PPE availability both directly through manufacturing constraints and indirectly through shortages of raw materials and components used in production.

Secondary supply chain disruptions prove particularly problematic because they remain difficult to anticipate given economic volatility and geopolitical events. Healthcare organizations must navigate complex supplier networks where disruptions at any point can create widespread availability issues.

Inventory Management Inefficiencies

Inefficient inventory management practices create substantial operational and financial burdens for healthcare organizations. Nearly 40% of providers had to cancel or reschedule procedures at least quarterly in 2023 due to product shortages, representing direct revenue losses and compromised patient access to care.

Traditional inventory management approaches often rely on manual processes, spreadsheet-based tracking systems, and reactive ordering practices. These methods lack the sophistication necessary to predict demand fluctuations, optimize stock levels, or provide real-time visibility into supply availability across multiple locations.

Overstocking presents equally significant challenges, tying up valuable capital in excess inventory while increasing storage costs and waste from expired products. Healthcare organizations struggle to balance adequate supply availability with efficient capital utilization.

Staffing and Expertise Shortages

The healthcare supply chain workforce faces unprecedented challenges as competition for trained professionals intensifies across industries. Many supply chain workers have transitioned to sectors offering more stable work environments, creating expertise gaps within healthcare organizations.

This staffing crisis compounds existing supply chain management challenges. Remaining team members face increased workloads while organizations struggle to maintain institutional knowledge and develop strategic supply chain capabilities. The shortage of experienced supply chain professionals limits organizations’ ability to implement advanced technologies and optimization strategies.

Reactive Management Approaches

Perhaps the most significant obstacle to modernizing healthcare supply chain management lies in organizations’ continued reliance on reactive approaches rather than proactive strategies. Traditional supply chain management focuses on responding to immediate needs rather than anticipating future requirements and potential disruptions.

Reactive approaches limit organizations’ ability to leverage data analytics, predictive modeling, and strategic partnerships that could enhance supply chain resilience. This reactive mindset prevents healthcare organizations from building the systematic capabilities necessary to navigate increasingly complex supply chain environments.

Strategic Solutions for Supply Chain Optimization

Advanced Automation Technologies

Healthcare supply chain automation represents a transformative approach to managing procurement, inventory, and distribution processes. Automation technologies simplify supply management workflows, reduce manual errors, improve data accuracy, and prevent both supply shortages and overstocking situations.

Enterprise Resource Planning (ERP) systems integrate inventory tracking, supplier management, and demand forecasting within unified platforms. This integration enhances decision-making capabilities, reduces operational costs, and provides comprehensive visibility into supply availability and usage patterns across healthcare organizations.

Automated ordering systems can maintain optimal stock levels based on historical consumption data, seasonal variations, and predictive analytics. These systems reduce administrative burden while ensuring consistent supply availability for patient care activities.

AI-Driven Predictive Analytics

Artificial intelligence and machine learning technologies leverage historical and real-time data to generate accurate demand predictions and identify potential supply chain disruptions before they impact operations. Predictive analytics help healthcare providers prepare for demand spikes, optimize purchasing decisions, and avoid stockouts.

AI systems can analyze complex data patterns including patient volume trends, seasonal variations, procedure scheduling, and external factors that influence supply consumption. This analysis enables proactive inventory management and strategic sourcing decisions that enhance supply chain resilience. This would prove crucial during periods of global pandemics and disease management.

Advanced analytics platforms can identify equipment and supplies most likely to become critical during various potential disruption scenarios, enabling organizations to develop targeted contingency plans and strategic reserves.

Dynamic Sourcing Strategies

Building supply chain resilience requires organizations to replace sole-source suppliers with diversified sourcing strategies that include multiple suppliers and local alternatives. Dynamic sourcing approaches help healthcare organizations avoid costly emergency procurement while maintaining reasonable inventory investment levels.

Strategic supplier diversification involves developing relationships with primary, secondary, and emergency suppliers for critical items. This approach provides flexibility during disruptions while maintaining competitive pricing through ongoing supplier performance evaluation.

Local and regional sourcing strategies can reduce transportation costs, delivery times, and vulnerability to global supply chain disruptions. Healthcare organizations should evaluate local supplier capabilities and develop partnerships that support both routine operations and emergency response requirements.

Real-Time Inventory Management Systems

Modern inventory management systems provide real-time visibility into product locations, quantities, and movement patterns across healthcare organizations. Advanced systems can achieve 99.9% inventory accuracy while reducing administrative overhead and optimizing stock levels.

RFID and IoT tracking technologies enable comprehensive monitoring of medical equipment, pharmaceuticals, and supplies throughout healthcare facilities. These technologies reduce theft, improve inventory accuracy, and provide detailed visibility into asset utilization patterns.

Cloud-based inventory management platforms facilitate better communication between suppliers, distributors, and healthcare organizations through centralized data storage and enhanced reporting capabilities. These platforms support collaborative planning and information sharing across entire supply chain networks.

Organizational Strategy Enhancement

Elevating supply chain management within organizational hierarchies represents a critical strategic imperative. Supply chain management should achieve equal status with information management, operations management, and financial management rather than functioning as a support service.

Healthcare organizations must develop comprehensive success metrics that extend beyond traditional cost reduction measures to include supply chain return on investment, patient care impact, and operational resilience indicators. These metrics should drive strategic decision-making and resource allocation across supply chain activities.

Data analytics capabilities should identify operational inefficiencies and optimization opportunities throughout supply chain processes. Organizations should consider innovative approaches such as equipment rental programs for rarely used items to optimize capital utilization while maintaining clinical capabilities.

Implementation Considerations and Future Outlook

Successful supply chain transformation requires systematic change management that addresses technology adoption, process redesign, and organizational culture development. Healthcare organizations must invest in staff training, technology infrastructure, and strategic partnerships that support long-term supply chain excellence.

The transition from reactive to proactive supply chain management demands comprehensive data integration and analytical capabilities. Organizations should view supply chains as critical sources of operational intelligence that feed into advanced analytics engines, ultimately enhancing efficiency across all healthcare operations.

As healthcare continues to evolve toward value-based care models and population health management, supply chain optimization becomes increasingly important for achieving clinical and financial objectives. Organizations that invest in advanced supply chain capabilities position themselves for sustained success in an increasingly complex healthcare environment.

Healthcare supply chain management stands at the threshold of significant transformation. Organizations that embrace advanced technologies, strategic partnerships, and proactive management approaches will achieve competitive advantages while enhancing patient care delivery and operational resilience.

If you want to learn more about how Avetus Partners can support your Supply Chain Management issues, reach out to John Brooks, our Partner and SCM SME at john.brooks@avetus.com.